Most pressure equipment and piping systems currently in operation were built prior to the industry having a valid technical basis to establish low temperature limits to prevent catastrophic brittle fracture.

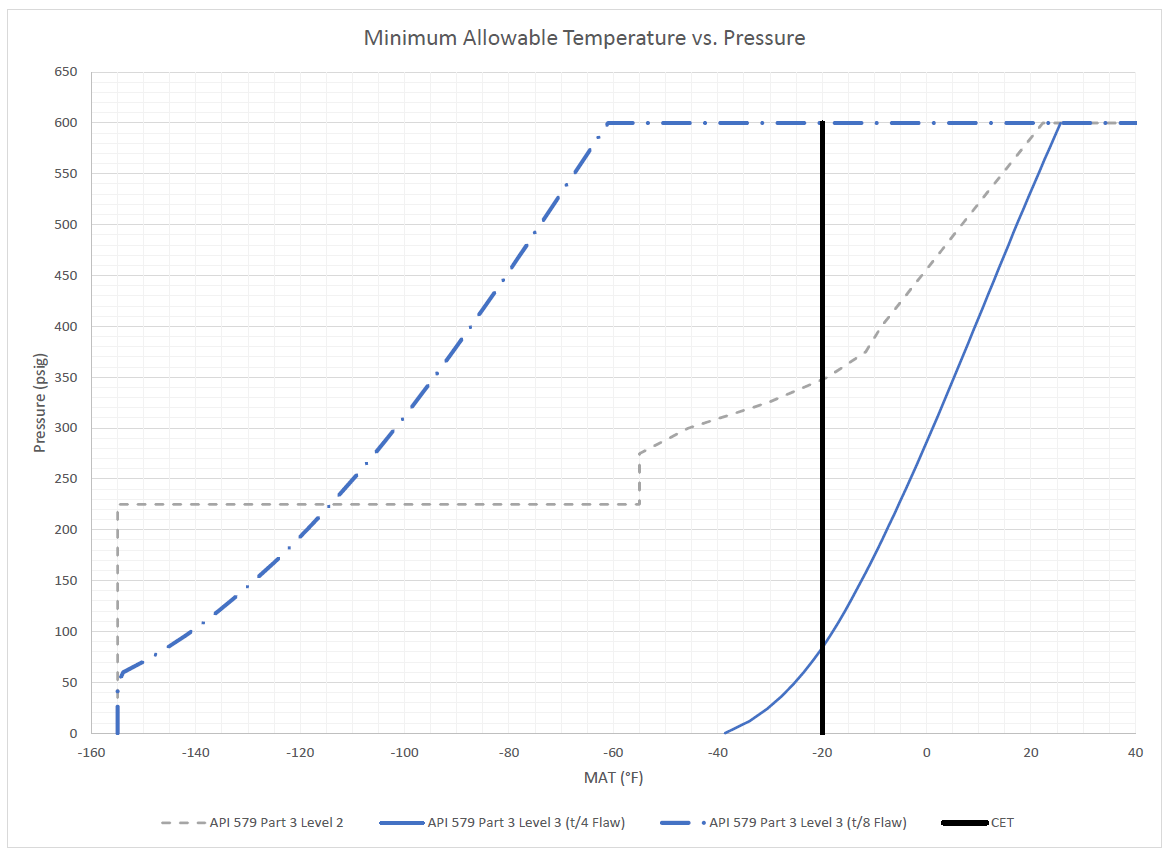

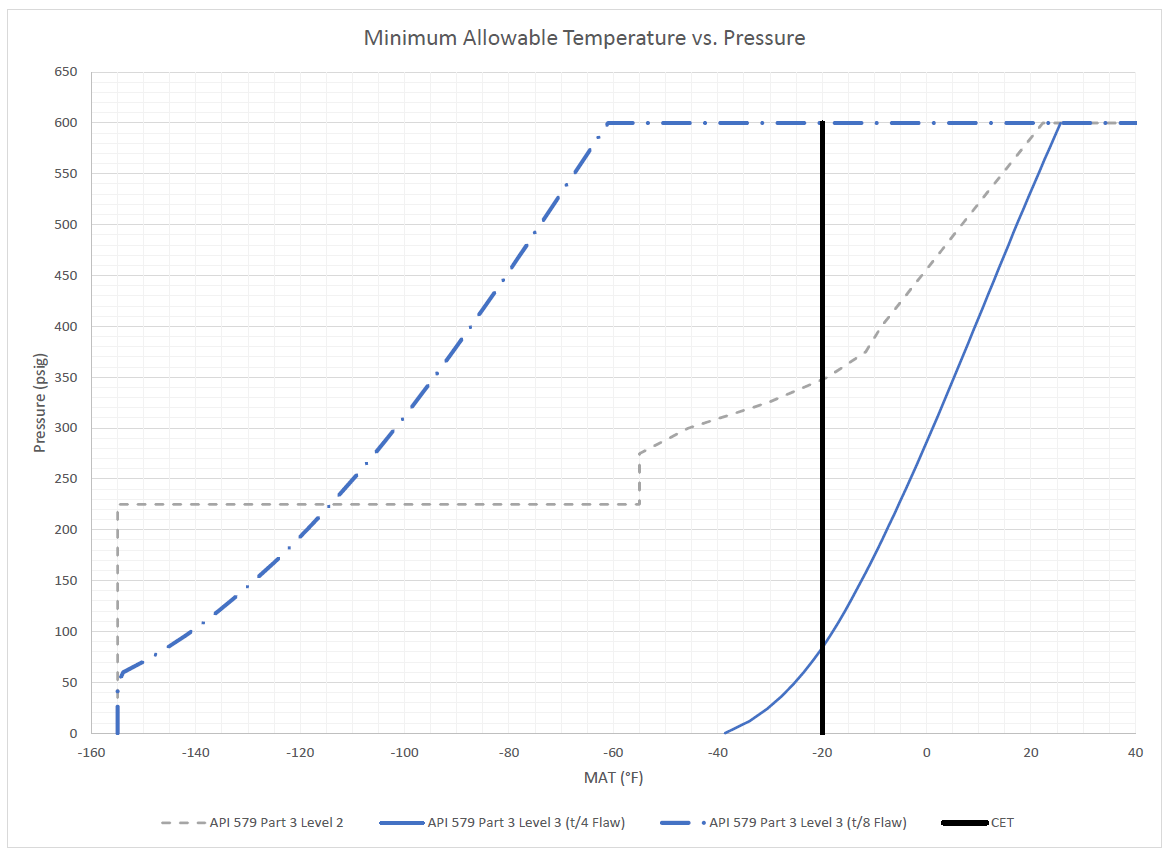

Utilize API 579-1/ASME FFS-1 (API 579) Part 3 and Part 9 and WRC Bulletin 599 to establish the minimum allowable temperature (MAT) limits as a function of operating pressure. If the project involves multiple equipment items, develop a project technical protocol document to establish the technical basis for the project and to ensure consistency with the assumptions, methodologies, and deliverables.